|

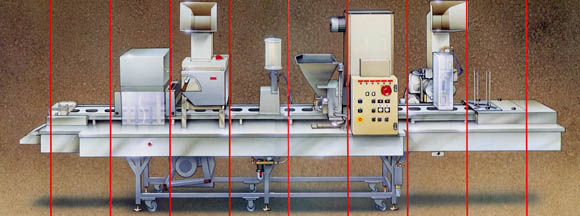

The Linamatic is designed for the volume production of pies and pastry products of the highest quality.

It incorporates the proven experience of Peerless in the design and production of pastry moulding equipment over the last 50 years. Every Linamatic is built to the highest engineering standards, with emphasis on hygiene and safety, to a Quality Assurance Scheme that is assessed by N.Q.A to meet the requirements of BS5750 Part 1 and ISO 9001.

The Linamatic is fully automatic in operation. The only labour needed is that required to keep the hoppers and dispensers topped-up and handle the finished pies as they leave the machine. A single Linamatic can produce millions of pies a year - and that is in the course of a single 8 hour shift day, five days a week!

Each machine is built to meet your specific requirements. With it's modular construction, an extremely wide range of depositors, moulders and fillers can be combined to meet the production requirements of most pastry products - pies, tarts, flans, quiches and custards made in aluminum foils, tins or hoops. A single machine can also be designed to produce a range of different products and changing from one to another is a simple operation that can be completed in under 15 minutes.

|

|

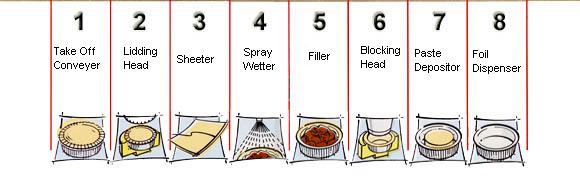

1 Take Off Conveyer

Continuously operated conveyer discharges the finished pies to a table or carousel.

2 Lidding Head

Seals the pie lid to the base, forms the crimp decoration and cuts off excess paste with pneumatic action for clean seperation.

3 Sheeter

Three roll sheeter produces a continuous roll of pastry from which the pie lid will be formed. It can be adjusted to produce the thickness and width of pastry required to match the product.

4 Spray Wetter

Pneumatically operated impulse water atomiser to wet the edges of the pie base for sealing the pie lid.

5 Fillers

Wet Filler: Deposits a measured quantity of filling in the moulded pie base. The Wet Filler illustrated is suitable for any filling with a free-flowing consistency with diced solids up to 18mm - fruit, jam, minced meat, chicken & mushroom, steak & kidney, etc. It has a large capacity stainless steel hopper and sensors ensure no pie, no deposit.

Dry Meat Filler: Is suitable for stiffer products, such as pork pie filling and chilled fillings for meat pies which are not free-flowing.

6 Blocking Head

Moulds the pie base using a double action heated die system to give superb results, even with deep products. The control panel is usually fitted to the Blocking Head to provide complete control over all units from a convenient central point.

7 Paste Depositer

Deposits in the foil the correct quantity of pastry for the product being made. The unit is fitted with a high capacity stainless steel hopper and the quantity of deposit can be controlled to an accuracy of +/- 3 grams.

8 Foil Dispenser

Positions an aluminum foil on the conveyer. Magazines are quickly interchangeable to suit your range of products. Tins or hoops would normally be hand loaded using guides provided to ensure accurate location. If a cut-out on the belt is missed sensors prevent any filling being deposited.

|

|

For The Production Of Lidded Pies

The Linamatic can mould, fill and lid up to 2,000 pies an hour in aluminum foils. The pies can be oval or round with dimensions up to 180mm diameter and filled with steak & kidney, chicken & mushroom, apple or other fruits, jam, minced meat or any other filling that will flow.

For The Production Of Flans

The Linamatic can mould and fill up to 2,000 flans an hour in tins, which are hand placed on the conveyer, or in foils when they are automatically dispensed. The product can be up to 180mm diameter and filled with egg mixes for quiches or custard, jam and fruit fillings.

For The Production Of Pork Pies

The Linamatic can mould, fill and lid up to 2,000 pork pies an hour in foils, tins or hoops which are hand placed on a platen conveyer. The pies can be up to 1 1/2lb in weight, with dimensions of approximately 160mm diameter by 30mm deep, or deep pies up to 120mm diameter by 60mm deep. As well as pork pie filling, the machine could be used for chicken & ham or other fillings that are too dense to flow.

For The Production Of Small Pies

The Linamatic can mould, fill and lid up to 4,000 small pies an hour in aluminum foils. The pies can be up to 100m diameter, or 135mm x 100mm oblong and ar indexed along the machine side by side, or in pairs along the line of the conveyor, doubling the production rate. Fillings on this system could be meat, fruit, jam or any other filling that will flow. By changing the Wet Fillers for Dry Depositors the system could be used to produce small pork pies. Omit the Lidding Head and the system would be suitable for the production of small open products or empty pastry shells.

These are just a few of the many possible configurations that can be built to meet your precise production needs. Our Bakery Specialist will be pleased to discuss how the Linamatic can be tailored for your requirements.

|